HYDRAULIC DRIVER FOR HELICAL PILE INSTALLATION

• Of low-maintenance under any conditions

• Suitable for private and commercial use

• They will twist the piles where heavy machinery will not pass

Get the price

Thank you for your application!

Our managers will contact you soon.

MODIFICATIONS OF THE HERCULES HYDRAULIC HELICAL PILE DRIVER MANUFACTURED BY WINTTEK

HERCULES Hydraulic Helical Pile Driver

|

Description |

GS 21 |

|

Pressure |

|

|

- nominal, MPa |

16 |

|

- maximum pressure, MPa |

21 |

|

Nominal volumetric supply, l/min |

21,0 |

|

Maximum volumetric supply, l/min |

35,0 |

|

Power, KW (HP) |

11 (15), 12,5 (17), 13,6 (18,5) |

|

Weight with filled discharge tank, kg |

108 |

|

Oil volumetric capacity of the discharge tank and hydraulic system, l |

14 |

|

Fuel tank capacity, l |

6,5 |

|

Engine oil volume, l |

1,1 |

|

Air cooling |

Natural |

|

Reversing mechanism availability |

Yes |

|

HPH |

At the Station 2 by 7 meters. |

|

Dimensions, mm |

1265х768х769 |

|

- with the handles removed |

855х768х769 |

Hydraulic rotator

|

Operating pressure, MPa |

From 10 to 16 |

|

Volumetric supply not less than, l/min |

21 |

| Torque, Nm | 5500 to 8700 |

|

Rotation speed, r/min |

|

|

- nominal |

5 |

|

- maximum |

6 |

|

- minimum |

2 |

|

Weight with a rack, kg |

74 |

| Dimensions without additional lever and adapter for screwing piles, mm | 1263x607x140 |

HERCULES Hydraulic Helical Pile Driver

|

Description |

GS 21 |

|

Pressure |

|

|

- nominal, MPa |

16 |

|

- maximum pressure, MPa |

21 |

|

Nominal volumetric supply, l/min |

21,0 |

|

Maximum volumetric supply, l/min |

35,0 |

|

Power, KW (HP) |

11 (15), 12,5 (17), 13,6 (18,5) |

|

Weight with filled discharge tank, kg |

108 |

|

Oil volumetric capacity of the discharge tank and hydraulic system, l |

14 |

|

Fuel tank capacity, l |

6,5 |

|

Engine oil volume, l |

1,1 |

|

Air cooling |

Natural |

|

Reversing mechanism availability |

Yes |

|

HPH |

At the Station 2 by 7 meters. |

|

Dimensions, mm |

1265х768х769 |

|

- with the handles removed |

855х768х769 |

Hydraulic rotator

|

Operating pressure, MPa |

From 10 to 16 |

|

Volumetric supply not less than, l/min |

21 |

| Torque, Nm | 8700 |

|

Rotation speed, r/min |

|

|

- nominal |

5 |

|

- maximum |

6 |

|

- minimum |

2 |

|

Weight with a rack, kg |

74 |

| Dimensions without additional lever and adapter for screwing piles, mm | 1263x607x140 |

HERCULES Hydraulic Helical Pile Driver

|

Description |

GS 36 |

|

Pressure |

|

|

- nominal, MPa |

25 |

|

- maximum pressure, MPa |

30 |

|

Nominal volumetric supply, l/min |

36,0/21,6/14,4 |

|

Maximum volumetric supply, l/min |

54,0/32,4/21,6 |

|

Power, KW (HP) |

12,5 (17), 13,6 (18,5) |

|

Weight with filled discharge tank, kg |

118 |

|

Oil volumetric capacity of the discharge tank and hydraulic system, l |

14 |

|

Fuel tank capacity, l |

6,5 |

|

Engine oil volume, l |

1,1 |

|

Air cooling |

Forced |

|

Reversing mechanism availability |

Yes |

|

HPH |

Customer Supplied, length is available upon request. |

|

Dimensions, mm |

1260х783х769 |

|

- with the handles removed |

860х783х595 |

Hydraulic Rotator

|

Operating pressure, MPa |

From 10 to 16 |

|

Volumetric supply not less than, l/min |

21 |

| Torque, Nm | 5500 to 8700 |

|

Rotation speed, r/min |

|

|

- nominal |

5 |

|

- maximum |

6 |

|

- minimum |

2 |

|

Weight with a rack, kg |

54 |

| Dimensions without additional lever and adapter for screwing piles, mm | 1263x607x140 |

HERCULES Hydraulic Helical Pile Driver

|

Description |

GS 36 |

|

Pressure |

|

|

- nominal, MPa |

25 |

|

- maximum pressure, MPa |

30 |

|

Nominal volumetric supply, l/min |

36,0/21,6/14,4 |

|

Maximum volumetric supply, l/min |

54,0/32,4/21,6 |

|

Power, KW (HP) |

12,5 (17), 13,6 (18,5) |

|

Weight with filled discharge tank, kg |

118 |

|

Oil volumetric capacity of the discharge tank and hydraulic system, l |

14 |

|

Fuel tank capacity, l |

6,5 |

|

Engine oil volume, l |

1,1 |

|

Air cooling |

Forced |

|

Reversing mechanism availability |

Yes |

|

HPH |

Customer Supplied, length is available upon request. |

|

Dimensions, mm |

1260х783х769 |

|

- with the handles removed |

860х783х595 |

Hydraulic Rotator

|

Operating pressure, MPa |

From 10 to 16 |

|

Volumetric supply not less than, l/min |

21 |

| Torque, Nm | 8700 |

|

Rotation speed, r/min |

|

|

- nominal |

5 |

|

- maximum |

6 |

|

- minimum |

2 |

|

Weight with a rack, kg |

54 |

| Dimensions without additional lever and adapter for screwing piles, mm | 1263x607x140 |

HERCULES HYDRAULIC HELICAL PILE DRIVER - TECHNICAL FEATURES

- The unique design of the oil tank and its capacity of 14 litres which has no analogues;

- The engine mounting to the frame is performed with the use of professional anti-vibration mounts that eliminates any vibrations which have a destructive impact on hydraulic equipment;

- Removable handles for convenient transportation;

- The reel for high-pressure hoses (HPH) storage placed on the power unit casing helps to eliminate their damage while transportation and moving around the facility.

- Available in three versions: with a torque of 7000, 8700 and 10900 Nm.

- It is operated in operating temperature conditions ranging from +40 °C to -40 °C.

- GS-21 serial production - always readily available, GS-10900 and 7000 - custom-built.

- Significantly exceeds electric helical pile drivers in terms of technical characteristics, functionality and load life.

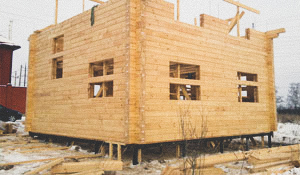

OUR HYDRAULIC HELICAL PILE DRIVER IS IDEAL FOR TIGHTENING THE FOLLOWING TYPES OF PILES

PILES OF 76 MM IN DIAMETER

under the gazebo, pier, porch

PILES OF 89 MM IN DIAMETER

under the extension, terrace, gazebo

PILES OF 108 MM IN DIAMETER

under the bathhouse, garage, house, hangar

PILES OF 57 MM IN DIAMETER

under the greenhouse, fence, palisade

PILES OF 133 MM IN DIAMETER

under the house, hangar, garage

PILES FOR ENGINEERING WORKS

raising the house, transferring it to a new foundation base

HOW DOES HERCULES HYDRAULIC HELICAL PILE DRIVER WORKS, STEP BY STEP INSTRUCTIONS

1. The hydraulic power unit is connected to the rotator with the help of quick-release connection.

2. The hydraulic power unit engine starts and warms up.

3. The pile is installed vertically in a pre-made sump.

4. The rotator is then installed on the pile and fixed with a stud.

5. The reinforced lever and the extension arm are bolted on.

6. The operator then starts the rotator.

7. One assembler uses a level to control the vertical position of the pile, the other holds the extension arm.

8. When the pile reaches the required position, the engine is switched off, the pressure in the hydraulic system is relieved and the rotator is dismantled.

SEE HOW HERCULES HYDRAULIC HELICAL PILE DRIVER WORKS IN WINTER CONDITIONS

• The simplicity and reliability of the design allows to work even in winter at temperatures down to -40ºC.

• Can be used in environments where electrical equipment (power tools) cannot be used due to electrical safety reasons.

• The ability to install piles in any hard-to-reach places where heavy machinery cannot drive up and space for manual screwing is limited.

To learn more about the equipment characteristics, please contact our specialist.

Leave us a request and we will definitely contact you!

Contact us

Your message has been sent sucessfully